NJR offers hygiene stainless steel fabrication service. The whole service includes custom metal fabrication stainless steel containers and vessels and tanks, stainless pipework pipe and fittings.

The products of NJR are mainly used in the pharmaceutic industry. They can also be used in the food, skin care products and fine chemicals industry which all have a high standard of the hygiene condition during the manufacturing process. The equipment used for production must stay clean or sometimes even sterile. Therefore, making the pharmaceutic production equipment out of the precision stainless steel can be a great method to achieve the standard.

NJR has top skill in the fabrication in the pressure vessel, welding and so on. It provides various of precision stainless steel equipment for clients in pharmaceutical, food industry. All machines adopt hygienic grade 304 or 316L stainless steel. The parts needed to contact materials are precision polishing finish to make sure no remain during your production.

Fully automatic CIP cleaner can clean and sterilize in a closed method without disassembly. It’s mainly used in the biological fermentation, pharmaceutical industry. It can also be used in the beverage, dairy, juice, beer, sugar manufacture industries.

CIP system is a central integrated system. With conductivity gauge and PLC control system, it can automatically clean in line.

During the pharmaceutical process, there will be a lot of waste ware. The wastewater disinfection system produced by NJR is specially designed to eliminate the bacterial and virus in the wastewater to avoid contamination.

The system is mainly used in pharmaceutical industry which can harvest, ultra-filter, purify and inactivate with volume ranging from 50L -5000L.

The strict standard NJR hold for the stainless steel pharmaceutical equipment has also passed to the production of stainless steel piping system. All sanitary pipelines, jacketed pipe works, fittings and pumps are made from hygienic grade 304, 316L stainless steel to avoid contamination of materials.

NJR eliminates all the dead space in the piping systems and decrease the pressure loss of pipes.

NJR can design sterile heat exchanger according to clients’ requirements. It’s an ideal pharmaceutical heat transfer equipment which can heat and cool the infusion and medicine and condense the sterile steam. Its volume ranging from 0.1m²-10m². Since it meets the FDA and CGMP standards, it is widely used in pharmaceutical, food, biology processing and other industries which have a high standard for the sanitary level.

Sanitary diaphragm valves are used for fluid control and switch and also widely used in the sanitary and sterile processing in pharmaceutical industry. Compared with other valves, it’s easier to clean and can treat material with particles better. When it comes to the control of flow rate, the cavitation is less.

The magnetic agitator is mounted on the bottom of mixing tanks at a low liquid level to make a uniform concentration.

Since it keeps suspension when it’s working or closing down, there is no friction between the bearing and rotator so that the bearing will not distort because of the heat released by friction.

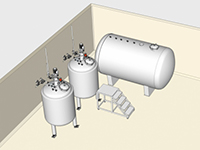

Stainless Steel Tanks and Precision Vessels Fabrication Service

NJR is a professional pharmaceutical stainless steel vessel fabricator. Based on years of experience, profession knowledge and ability to produce, NJR offers you one-stop solutions for clean stainless steel vessels.

NJR uses food grade stainless steel such as 316L, 304 and so on as the raw material to make different stainless steel products like stainless steel pressure vessel, reactor, tank for pharmaceutic production. The inner surfaces of the equipment have all been polished with Ra less than 0.28μm, which means that the surface of stainless steel has no holes so that nothing can remain in the equipment. It makes sure the products are absolutely sanitary.

There are some classic stainless steel products for you reference. No matter what kind of stainless steel products you want, for example, custom stainless steel containers or one-stop solutions for all the process in pharmaceutical formulations industry, NJR can meet your requirements.