Pharmaceutical Gels Mixing and Agitation Tanks

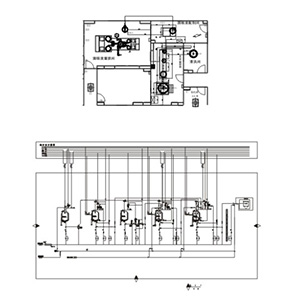

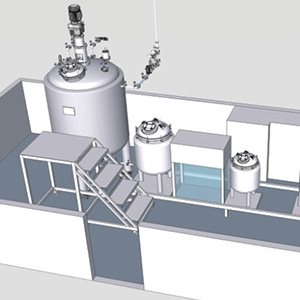

Gels are mainly composed of pure water and gelatin. One formulation and processing system used for gel production is shown below.

Project time: 2017

Client address: Hunan province

Product: gels

URS

- The formulation process should be carried out under temperature ranging from 20℃ to 100℃, with relative difference are less than 2℃.

- The maximum filling coefficient is no more than 80%

- The storage tank should have vacuum feeding function and reliable sealing capability, which can sustain -1 bar vacuum.

- The collagen of gel is easy to stick onto the inner surface of tank and put a bad influence on reaction. Hence, it should be solved prop

Plan in detail

- According to the URS, live steam is introduced to jacket on the vessel to heat the vessel, avoid direct heat and make sure the temperature uniformity.

- Calculate the mixing amount and control the volume of reactor. Make sure it satisfies the maximum filling factor and minimum mixing amount.

- Equip with vacuum tanks system to make the reaction vessel sustain both positive and negative pressure.

- Install scraper on the agitator shaft and make the scraper close to the tank interior. The material of scraper is food grade PTEE, which can sustain high temperature and is anti-corrosive with limited adhesion.