Pharmaceutical Stainless Steel Vessels and Tanks For Syrup Production

Since the syrup is taken orally, the production of it must consider the feature of human digestion system. However, the concentration of syrup is usually so high that it’s quite viscous. Hence, the filtration efficiency is lower. Usually, according to client’s requirement, the pore size of filter is between 30 um to 80 um.

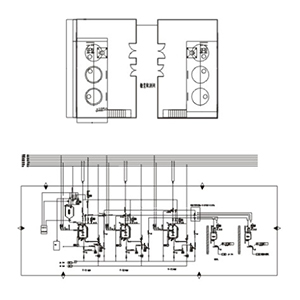

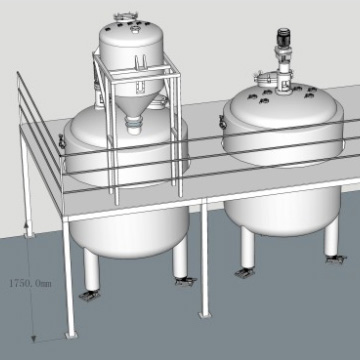

One formulation system used for syrup production is shown below for your reference.

Project time: 2016

Client address: Shanxi province, China

Product: syrup

URS

The client is a professional pharmaceutical company so that they require that the design, fabrication, installment and test of the project should all meet the following standards:

- good manufacturing practice for drugs (2010) SFDA

- GB150.1~150.4-2011 pressure vessel

- with CE mark

Plan in detail

- After adding quantitative pure water to the formulation tank and heating it to 100 ℃, add honey, raw material, auxiliary material and boil.

- When the material cool down to 50℃,sample it and carry on the first filtration if the sample is qualified. After filtration, the material is transferred to three 3000L cooling tanks.

- 12h, 24h and 48h of cooling are carried out desperately in three cooling tanks. Then filter again and transfer all material into three 3000L storage tanks.

- Carry out filtration for the third time and transfer material into buffer tank

- After the compounding, all tanks and pipes should go through the SIP system. Tanks are heated into 85℃ to run pasteurization circularly.